High-Quality Forklift Truck Safety Signs for Enhanced Storage Facility Safety

High-Quality Forklift Truck Safety Signs for Enhanced Storage Facility Safety

Blog Article

Trick Considerations for Creating Effective Forklift Security Indications

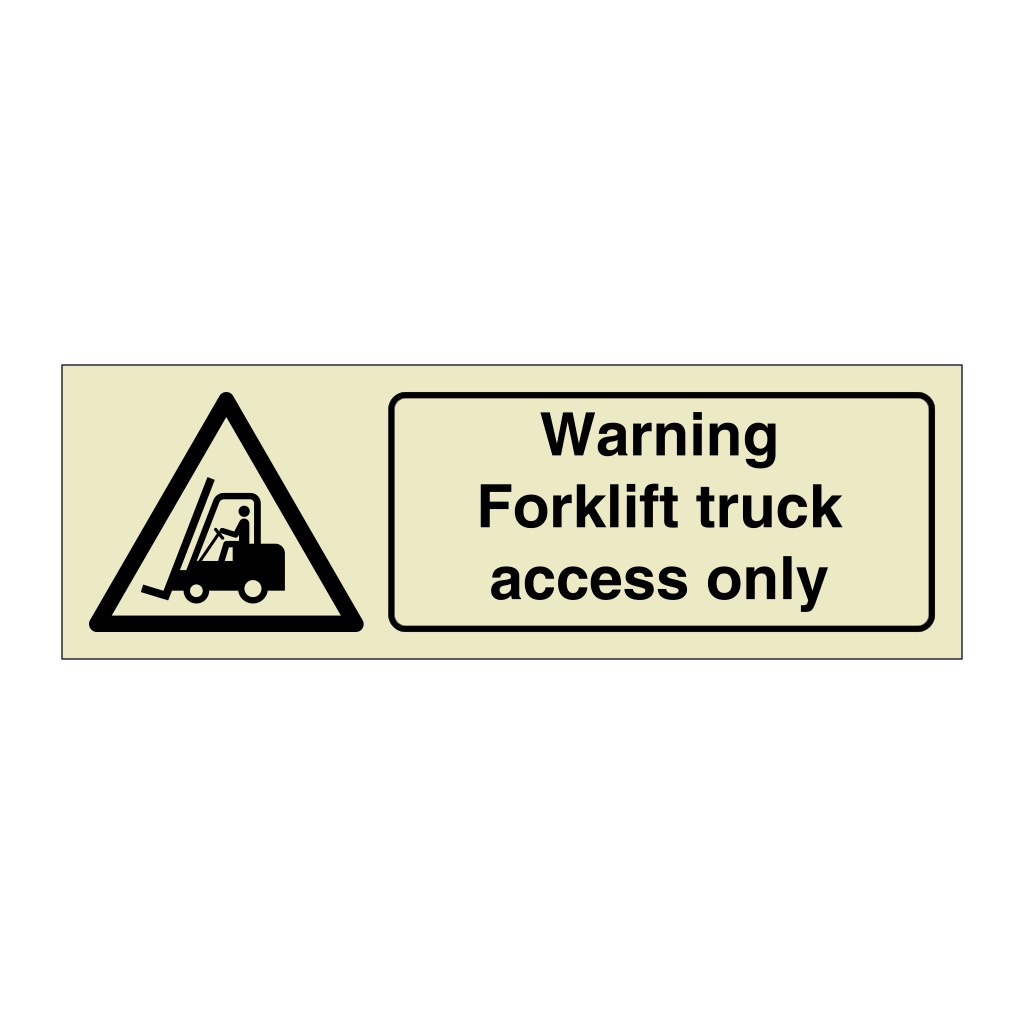

When designing effective forklift security indications, it is essential to take into consideration numerous basic elements that collectively make sure optimal visibility and clearness. High-contrast colors coupled with big, clear sans-serif fonts substantially boost readability, particularly in high-traffic areas where fast understanding is crucial. forklift signs. Strategic positioning at eye level and using durable materials like light weight aluminum or polycarbonate more add to the durability and efficiency of these signs. Additionally, adherence to OSHA and ANSI standards not just systematizes safety and security messages yet likewise boosts conformity. To completely understand the complexities and ideal practices entailed, numerous added considerations advantage closer interest.

Shade and Contrast

While designing forklift safety and security indicators, the option of shade and comparison is vital to guaranteeing exposure and efficiency. Colors are not simply visual elements; they serve important useful purposes by sharing specific messages promptly and reducing the threat of accidents. The Occupational Security and Health And Wellness Administration (OSHA) and the American National Criteria Institute (ANSI) provide standards for making use of shades in safety and security signs to systematize their meanings. Red is generally utilized to represent prompt risk, while yellow signifies caution.

Efficient comparison in between the history and the message or symbols on the indication is similarly crucial (forklift signs). High contrast makes sure that the indicator is legible from a range and in varying illumination problems.

Using proper shade and comparison not just abides by governing requirements yet also plays an important function in preserving a secure working environment by making sure clear communication of threats and guidelines.

Font Style Size and Design

When creating forklift security indicators, the selection of typeface size and design is vital for ensuring that the messages are readable and rapidly comprehended. The main purpose is to enhance readability, especially in environments where quick details handling is important. The font dimension must be big sufficient to be read from a distance, fitting varying sight conditions and guaranteeing that employees can comprehend the indication without unnecessary strain.

A sans-serif font style is commonly suggested for security indications because of its clean and uncomplicated appearance, which boosts readability. Font styles such as Arial, Helvetica, or Verdana are typically chosen as they do not have the complex details that can cover critical information. Consistency in font style across all safety and security indications aids in developing an uniform and expert appearance, which better enhances the value of the messages being communicated.

In addition, emphasis can be achieved via strategic use of bolding and capitalization. Key words or expressions can be highlighted to attract prompt interest to essential instructions or warnings. Overuse of these strategies can result in visual clutter, so it is essential to use them deliberately. By meticulously picking proper font style dimensions and styles, forklift security signs can effectively communicate critical security details to all employees.

Positioning and Visibility

Making certain optimum positioning and exposure of forklift security indications is paramount in industrial settings. Proper indication positioning can substantially minimize the danger of crashes and enhance general office safety.

Illumination conditions likewise play a crucial function in presence. Indicators ought to be well-lit or made from reflective materials in poorly lit locations to guarantee they are visible at all times. Using contrasting shades can additionally improve readability, particularly in settings with differing light problems. By diligently thinking about these elements, one can make certain that forklift safety and security indications are both efficient and visible, thus cultivating a safer working environment.

Product and Toughness

Picking the appropriate materials for forklift safety indicators is essential to ensuring their long life and effectiveness in commercial environments. Given the harsh conditions typically run into in stockrooms and making facilities, the materials selected have to hold up against a range of stress factors, consisting of temperature level variations, wetness, chemical exposure, and physical influences. Resilient substratums such as aluminum, high-density polyethylene (HDPE), and polycarbonate are preferred choices as a result of their resistance to these elements.

Aluminum is renowned for its toughness and deterioration resistance, making it an exceptional selection for both indoor and outside applications. HDPE, on the other hand, offers remarkable effect resistance and can endure long term direct exposure to severe chemicals without breaking down. Polycarbonate, known for its high influence strength and quality, is usually made use of where visibility and longevity are extremely important.

Similarly crucial is the type of printing utilized on the indications. UV-resistant inks and safety finishings can considerably boost the lifespan of the signage by avoiding fading and wear triggered by extended exposure to sunshine and other ecological elements. Laminated or screen-printed surfaces offer additional layers of protection, guaranteeing that the essential safety details stays legible with time.

Spending in premium materials and robust production processes not just expands the life of forklift safety and security indicators however also reinforces a culture of safety and security within the office.

Conformity With Laws

Sticking to governing criteria is extremely important in the style and deployment of forklift safety and security indications. Compliance ensures that the indicators are not only reliable in conveying crucial safety and security info but likewise satisfy lawful commitments, consequently mitigating prospective liabilities. Various companies, such as the Occupational Security and Health Management (OSHA) in the United States, provide clear standards on the specifications of safety indications, consisting of color pattern, message dimension, and the inclusion of universally identified symbols.

To follow these he said policies, it is necessary to conduct a complete evaluation of relevant standards. As an example, OSHA mandates that safety indications have to show up from a range and include specific colors: red for danger, yellow for caution, and environment-friendly for safety and security guidelines. In addition, adhering to the American National Specification Institute (ANSI) Z535 collection can even more enhance the performance of the signs by standardizing the layout components.

Additionally, regular audits and updates of safety indications ought to be performed to ensure recurring click site conformity with any modifications in laws. Involving with licensed safety professionals during the layout stage can likewise be advantageous in guaranteeing that all governing requirements are met, which the signs offer their desired purpose properly.

Final Thought

Creating effective forklift security indicators needs cautious interest to shade comparison, typeface dimension, and design to make certain optimal presence and readability. Strategic positioning at eye degree in high-traffic locations boosts understanding, while making use of resilient products ensures long life in various environmental conditions. Adherence to OSHA and ANSI guidelines standardizes safety messages, and integrating reflective products enhances visibility in low-light circumstances. These factors to consider collectively add to a safer working setting.

Report this page